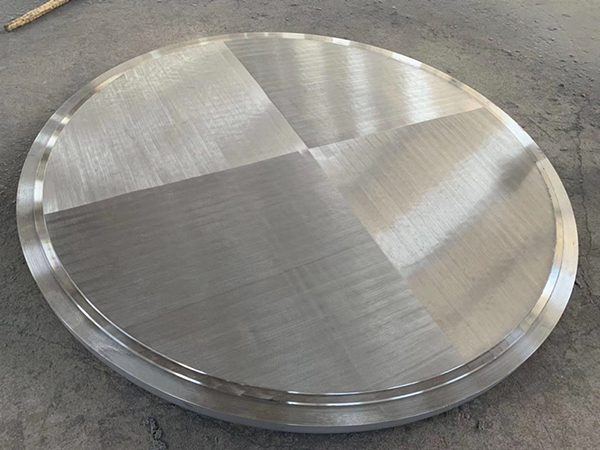

Titanium fittings

Material:Pure titanium, titan

Grade:TA1、TA2、TA3、TC4、TA9、TA10、TA18

thickness:0.3mm - 80mm

width:2m - 10m

height:小于9m

certificate:ISO 9001

standard:HG/T3651-1999 GB/T27684-2011 GB/T124569-2005 GB/T13401-2005 ASMEB16.9-2007

1. Product Introduction

Titanium tees mainly use titanium metal materials to oxidize the thin film in a strong corrosive environment, which has good stability and self-passivation ability. This feature can resist strong corrosion in a variety of harsh working conditions.

Whether the titanium tee can resist the corrosion of the working environment medium depends on the chemical stability of the "passive oxide film" on the surface in the corrosive medium. For neutral, oxidizing, and weakly reducing media environments, the "passive oxide film" itself has good stability. For reducing corrosive medium with high temperature or low PH value, in order to improve the stability of its "passive oxide film", it can be changed by adding corrosion inhibitors (such as air, water, heavy metal ions and anions, etc.) such as titanium surface ions Treatment, anodizing and other methods to improve the corrosion resistance and surface hardness of "titanium" in reducing media to meet the requirements of use

2. Product specifications

a. The ends of the equal diameter tees have the same size;

b. The main pipe connection size of the tee with the same diameter is the same, while the branch pipe connection size is smaller than the main pipe connection size.

3. Material

Commonly used materials TA1 (Gr1), TA2 (Gr2), TC4 (Gr5), customers need other materials can also be customized.

4. Performance standards

The chemical composition complies with GB/T 3625-2007 standard.

5. Standard value

| 化学成分参考标准 | |||||||||

|

牌号 |

Al |

V |

N≤ |

C≤ |

H≤ |

Fe≤ |

O≤ |

其他元素(单一) |

其他元素(总和) |

|

TA1 |

|

|

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

0.1 |

0.40 |

|

TA2 |

|

|

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

0.1 |

0.40 |

|

TC4 |

5.5-6.75 |

3.5-4.5 |

0.05 |

0.08 |

0.015 |

0.30 |

0.20 |

0.1 |

0.40 |

|

机械性能参考标准 |

||||

| 牌号 |

室温下力学性能,不小于 |

|||

|

抗拉强度 |

屈服强度 |

伸长率 |

断面收缩率 |

|

|

TA1 |

240 MPa |

170MPa |

25% |

30% |

| TA2 | 345MPa | 275 MPa | 20% | 30% |

| TC4 | 895MPa | 825 MPa | 10% | 20% |